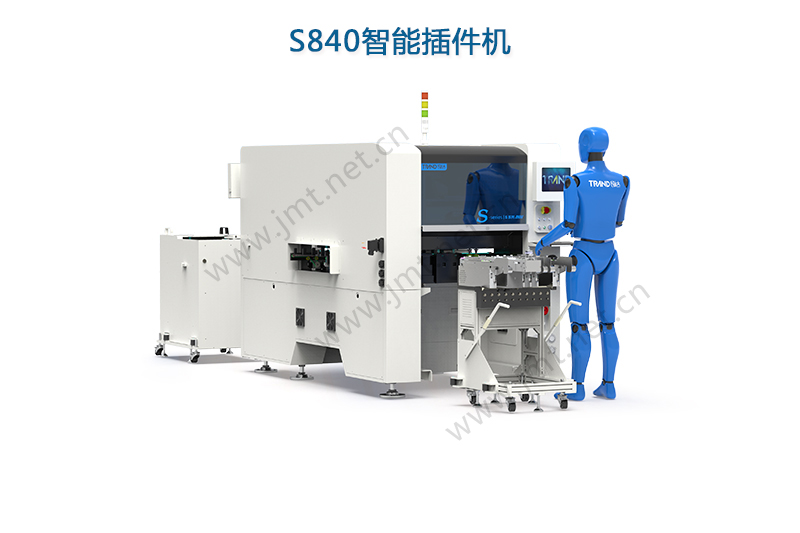

S840智能插件机

S840智能插件机,重新定义高效精密生产。它集插件、贴片、组装、贴标等多功能于一身,凭借0.1μs极速指令周期与±35μm超高精度,确保生产速度与良率双双跃升。设备搭载独立台车模组,实现分钟级机种切换,让柔性生产不再是难题;更配备前后双多光谱相机,精准识别从电容到内存条的各类元件,从根本上杜绝误插漏插。无论是复杂元器件还是混线生产,S840都能助您轻松应对,是提升产能与竞争力的理想解决方案。

The S840 intelligent insert machine redefines efficient and precise production.It integrates insertion, surface mounting, assembly, labeling and other functions , with 0.1μs speed command cycle and ±35μm ultra-high precision to ensures a significant increase in both production speed and yield.The equipment is equipped with an independent trolley set, enabling minut-level model switching, making flexible production no longer a problem. It is also equipped with dual multispectral cameras at the front and back,accurately identifying various components from capacitors to memory sticks, fundamentally eliminating the possibility of incorrect or missed insertions.Whether it's complex components or mixed-line production,the S840 can help you handle them with ease and is an ideal solution for enhancing production capacity and competitiveness.

| S840 产品规格 Specification | ||

机器尺寸 | 1500×2400×2100mm | |

机器重量 | 2600 kg | |

操作系统 | Windows | |

开门数量 | 双边 Double size | |

门板安全光栅 | 标配 | |

气源*1 | 0.5-0.65 MPa (ANR) | |

设计的最大功率 | 5.5 KW | |

正常运行功率*2 | 4KW | |

贴插轴数量 | 8 | |

贴插最大元件尺寸 | φ548 (40×40)mm | |

贴插元件高度 | ≤40mm | |

元件取料方式 | 吸嘴/ 夹爪 | |

最快贴插速度*3 / 每颗零件 | 0.6 S | |

贴插装精度(3ó) | ± 0.06mm | |

插入力量 | ≤29.4N | |

贴插方向 | 0-360° | |

贴插元件对象 | 各种连接器、开关按钮、变压器、端口插座、电容、电阻、集成芯片等元器件 | |

基板尺寸 | 70×70 ~ 410×550 mm | |

治具尺寸 | Max 410×500mm | |

基板厚度 | 0.6-2.0 mm | |

基板通过高度 ( 上/下) | 40 mm / 20 mm | |

基板最大重量 | 5 Kg | |

基板夹边宽度 | ≥5mm | |

基板固定方式 | 伺服顶板/气缸夹紧 Sero / Cylinder clamping | |

轨道*4 | 链条 | |

迸板方向 | 左→右 /右→左 R to L / L to R | |

轨道分段 | 3 | |

轨道调宽 | 自动 | |

轨道离地高度 | 900 ± 20mm | |

插件弯脚模组*5 | / | |

联机信号接口 | 标配 Standard Configuration | |

| MES 对接*6 MES Connection | 标配 | |

影像系统 | Mark CCD (Top) | 2 |

| Component CCD (Bottom) | 2 | |

供料器最大装载数 | 201立式编带 | 10 |

218立式编带 | ||

207立式编带折弯90 ° | ||

259立式编带 | 20 | |

254立式编带 | ||

202卧式编带 | 10 | |

222管装 | 20 | |

203管装 | 10 | |

205散料 | 8 | |

托盘供料器 | 2 | |

注:如多种类型供料器混合使用,则依实际情况确定使用数量 | ||

说明:

*1气源为大气压霜点:-17℃以下,微粒粉:粒径5μm以下,最高油分浓度:5mg/m3以下,另外机器安装时需要气源;

*2根据使用条件会发生变化;

*3视乎不同元件;

*4标准机是链条,可以定制皮带;

*5选配弯脚模组会取代顶板机构,弯脚范围请和我司相关人员索取;

*6只提供原厂设定信息. 需要配合客户系统可定制(选配项)。

Statement:

* 1 Air should be atmospheric frost point: under -17℃, Power Particles: under 5μm, The highest Oil content: under 5mg/m3 . In addition, it need air when machine setup;

* 2 Changed by the using condition;

* 3 Depends on different components;

* 4 The standard machine is chain conveyor, but it can be customized as belt;

* 5 Lead clinching unit will replace the PCB supporting mechanism;

* 6 Only provided the original data format, the rest should be customized.

简体中文

简体中文 English

English